Fact 1

‘Lean Manufacturing’ is now a concept in many production companies. Indeed, nowadays, we are seeing various initiatives on the shop floor for the implementation of the lean tool box. Just think of visual management in the world of production planning, SMED where reduction in turnover time is crucial, or the installation of a heijunka box to achieve load levelling.

In short, the industry is familiar with several examples of lean trajectories with the ultimate aim of achieving flow in your company by eliminating waste.

Fact 2

Furthermore, we also increasingly notice a growing interest in applying Lean in the warehouse and even towards the entire supply chain, the end-to-end value stream. This isn’t illogical when you consider that 7% of the cost price of a product is generated from production. And so, it’s certainly worth zooming in on the other 93%. All eyes, then, are fixed increasingly on the wider order-to-cash process and the integral supply chain. This is also being promoted strongly from QRM (Quick Response Manufacturing). Apart from this notion, there are also the current market trends:

1. A trend towards a ‘custom-made’ industry.

2. A trend towards rapid delivery.

Both trends ensure that the warehouse is scrutinised more strategically. The growing complexity in the market is becoming intolerable and financially unsustainable if you don’t build up a system in your logistical chain, your warehouse, to cope with this variation.

Levers

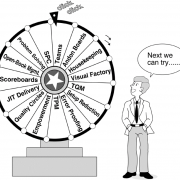

Just as it is best to deploy Lean or Operational Excellence in production as a system of different elements, this way of working can be applied in the warehouse in the same way. It’s a question of finding the right combination of the tools to meet the current demand from the warehouse.

Finally, a warehouse will never be able to operate as a robust unit purely by implementing 5S. It isn’t until it is supported by elements such as visual planning and standard work that it can respond flexibly to the ever-growing complexity of client demand. Similar lean warehouse programmes always yield good results.