It becomes a problem, however, as soon as you only focus on reducing waste! For example. Inventory is rightly preached as one of the biggest losses. Among other things, it causes additional transport of material. Inventory creates the need for extra space (with all the associated costs) and also creates sleeping capital, capital that could be invested elsewhere. But what do you do if this amount of stock is necessary in order to be able to deliver to your customers on time? Do you then blindly reduce this stock? The answer is logically no, but you would be surprised at the number of companies that fall into this trap after getting to know Lean.

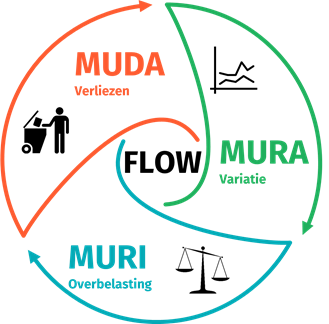

The reduction of Muda, the Japanese term for waste, cannot be carried out without taking the other 2 M’s into account, namely Mura (variation) & Muri (overload):

Muri, losses due to the overloading your people and/or machines

If you overstretch or overstress people and machines, you create safety risks, quality loss and even health problems.

Typical causes

- Workplace organisation that has not be thought through

- A lack of (preventive) maintenance, unreliable machines

- A lack of reliable processes

- A lack of the right tools

- Insufficiently trained staff

- Over-planning of the production equipment

- Excessive fluctuation of the customer demand

Mura, losses due to variation.

Variation can be found in every part of the process:

- Processes that are not well balanced

- Fluctuating customer demand

- Machine breakdowns and delays

- Variation created by downtimes (man/machine)

- Repetitive actions of a person or machine that deviate from the baseline

- Impact of defects

- Insufficient staff present

- Not having the right materials and tools

Muda, the standard 7 wastes

Over-Production, Inventory, Motion, Defects, Over-Processing transport & Waiting and don’t forget the human wastes: Talent, Focus and Communication waste.

Lean (Lean Manufacturing as well as Lean Office) is ultimately about creating flow. The above wastes, more specific the 7 technical wastes prevent this flow. The more you read and think about this topic the better your insight becomes that actually Muri and Mura are the cause of the majority of the 7 wastes. These two, how ever, are less known an addressed.

So if you want to become lean, first tackle the most critical variation steps in your end-to-end process. This is possible by applying our Lean Six Sigma methodologies. Make sure that your process is well staffed and the staff is well trained. Also address the technical variation in your process. Make sure machines and equipment is working like it should and is well maintained.

These actions will ensure that the overloading of the process becomes visible. Next step is to tackled this. In this way, you will already have eliminated a large part of the Muda.

Conclusion: Muda is a result of Muri and Mura. Blindly removing Muda will maybe remove the symptoms, but not the root causes!