What is Lean?

A pioneering business philosophy that originally originated at Toyota in Japan in the 1950s. Lean is a systematic approach to process optimisation, aimed at minimising waste and maximising efficiency. This globally recognised methodology emphasises continuous improvement and customer value creation. By implementing standardised processes, just-in-time production and employee engagement, Lean enables companies to reduce costs, improve quality and shorten lead times. Unlock your organisation's potential with Lean and stay competitive in today's dynamic business world.

What is Six Sigma?

Six Sigma originally originated at Motorola in the 1980s and has since spread as an effective approach to improving quality and reducing variation in processes. This systematic approach focuses on identifying and eliminating defects and aiming for only 3.4 defects per million opportunities. Through rigorous data analysis and statistical tools, Six Sigma helps organisations increase efficiency, reduce costs, systematically solve problems and improve customer satisfaction.

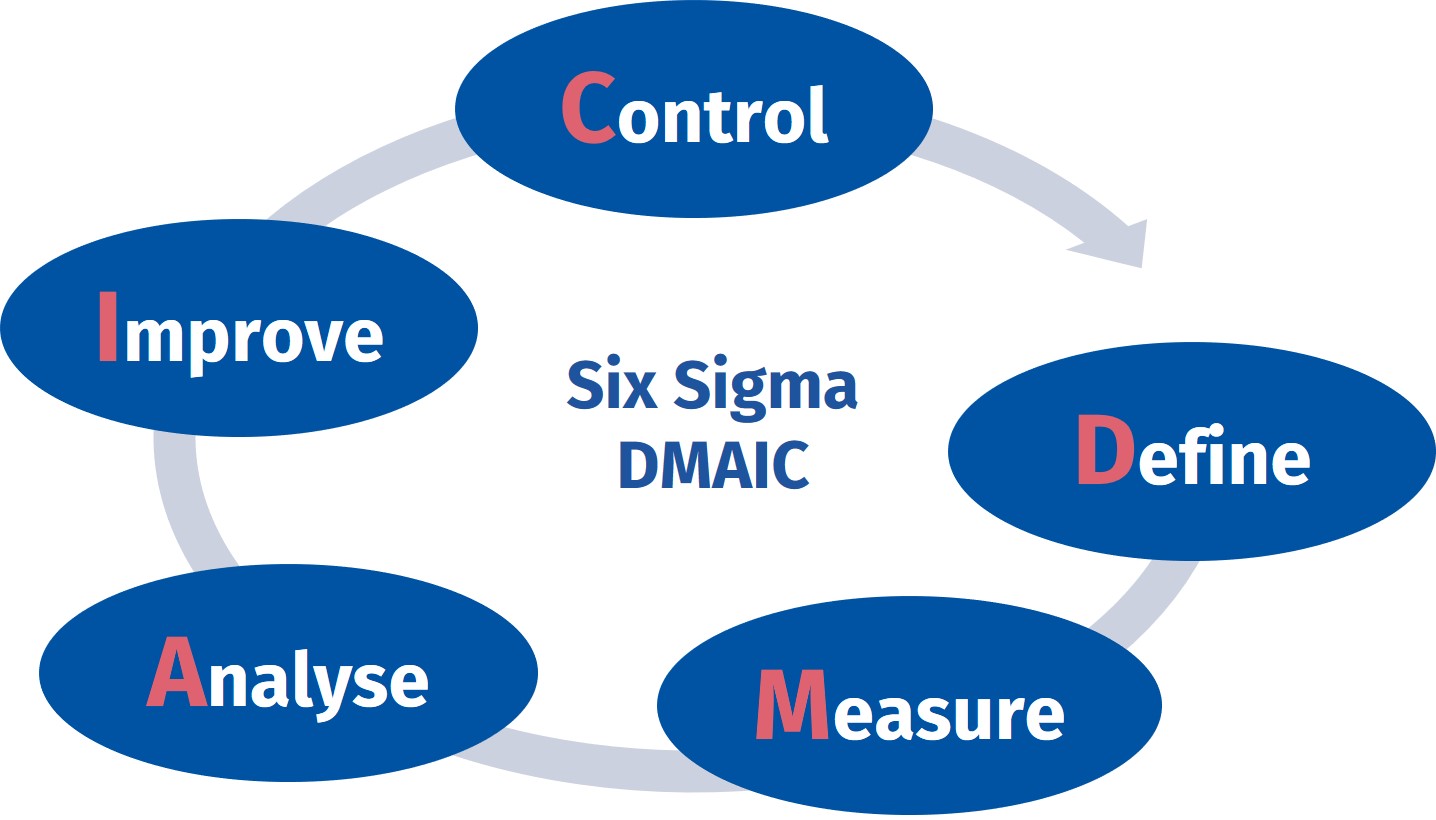

What is the roadmap for a Lean Six Sigma project?

The DMAIC (Define-Measure-Analyse-Improve and Control) approach is used, which provides concrete tools in each of the steps to solve product and process problems based on a ‘measuring is knowing’ philosophy.

Process problems e.g. quality, production or waste problems need to be tackled in a systematic way using project management principles.

Define

The “Define” phase covers following topics:

- Project charter with a clear definition of the problem, composition of the team and identification of the stakeholders

- Process mapping e.g. value stream mapping, process flow diagrams, SIPOC (supplier - input – process - output – customer)

- Investigation of internal and/or external customer requirements (voice of the customer) to quantify the quality specifications (CTQ: critical to quality)

- Definition of project goals

Measure

In the “Measure” phase the size and current state of the problem are mapped.

- Checking if the measurement system is adequate for correct measurements (Gage r&R)

- Identification of the most influencing factors through funnelling

- Fact driven funnelling: IS-IS NOT, pivot tables, data analytics

- Opinion driven funnelling: priority matrix, FMEA (Failure Mode and Effect Analysis)

- Collection of additional data about influencing factors

- Visualisation of current state of the problem by e.g. pareto and time series plots, process control charts and process capability indices

Analysis

In the “Analyse” phase the influencing factors are further explored to find the real root cause(s).

- Production, quality related problems root cause analysis tools are used

- Time or waste related problems typically lean tools are applied

Improve

In the “improve” phase potential solutions for the root causes are developed.

- Development possible solutions e.g. using brainstorming

- Selection of best solution(s) using decision matrix based on cost, impact, risk and/or other relevant criteria

- Implementation of the best solution(s) based on a detailed implementation plan using a stepwise “pilot” approach

- Start of monitoring the effect of the solution

Control

In the final “control” phase of the DMAIC approach, the solutions are secured in the organisational systems to make sure one does not fall back into old habits.

- Writing instructions and good documentation

- Training of the involved employees

- Monitoring results (statistical process control)

- Development of Process control plan and/or Quality control plan

After the “control” phase, the project is finished. It is of utmost importance to reflect on the way of working, to keep “lessons learned” for future projects.

At Stanwick, we understand the value of Green Belt Lean Six Sigma training and offer high-quality professional courses designed to propel your organisation and your personal growth to new heights. Contact us today and find out how our training courses can help you achieve your goals.